Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TF-X / KAAN / Hürjet Turkish Fighter & Trainer Aircrafts News & Discussions

- Thread starter silicon0000

- Start date

NGAD IS THE BEST

Elite Member

- Oct 29, 2020

- 10,545

- 4,149

- Country of Origin

- Country of Residence

But have capability to develop high thrust class engine by itselfWe won't agree on the other points but which engine is this? XF9

Please don't count an engine in development that was not put in serial production at least.

Japan has now given up independently developing its own next-gen fighter and the partnership with the UK/Italy will rely on an engine built on core Rolls Royce technology.

Nilgiri

INT'L MOD

- Aug 4, 2015

- 25,762

- 48,113

- Country of Origin

- Country of Residence

I do not have that inbuilt Turkish national that would cloud my judgement and think Turkey could get to within 10-20 years of US/Chinese fighter engine tech by the 2030s.

Its not about "inbuilt Turkish national".... its about do you have the knowledge on the subject at hand to the degree needed in first place.

If you don't, then its about simply not projecting your ignorance on the subject....with the whole "its impossible to catch up by even the 2030s for Turkiye"....without having the basic understanding on say what GE does with TAI, TEI and its RnD facility in eskisehir to begin with....given the what/where/why of the F-16 history in TurAF along with Turkish industrial intensity and ecosystem w.r.t NATO and EU proximity.

Among the other layers of conversation involving still other entities past GE....some already mentioned in this thread.

Its that simple.....dont project regarding things you know nothing about to begin with in the degree required for it.

Lot of Turks in their defence forum know my career experience on this subject for a reason. Its a long conversation and analysis I've had with them....sometimes on distinct components TEI is developing.

If Oscar, Quwa, hyperman and others on this thread aren't good enough for you, I can point you to the larger form conversation (concerning deep delve into the capital and HR Turkiye has already and is developing further) that is of far greater utility on the matter at hand than a perusal at wiki pages to fit this " inbuilt Turkish national" approach you assert.

But I feel you have made up your mind already anyway. Up to you whether you want to keep digging this hole some more though.

Nilgiri

INT'L MOD

- Aug 4, 2015

- 25,762

- 48,113

- Country of Origin

- Country of Residence

Where is the metallurgy sourcing going with all of that though?

That is probably the most protected aspect of the field.

The metallurgy is not that big a stumbling block now given the GE RnD facility and corps of engineers Turkiye has developed there in projects for last 10 - 20 years. That's how they have acquired the capital machinery needed for the local turboshaft project that has seen good progress (regarding single crystal and so on, that can be scaled now). TEI also is exporting commercial components to the LEAP engine and so on.

The issue at hand of vital importance is how the TF-6000 goes test + application + feedback wise now. This will give basis for larger projects to come and also what bargaining strength Turkiye has in approaching say RR, Pratt for consultancy in the TR motor, Kale routes.

This is where detailed design stuff will come into play with bigger designs, unforseen issues like bearings etc (past the material science on hand), but you need to tread the path to know how these things show up in first place. Turkiye is basically taking leaps where it can (and where its on offer) and other parts it has to build up the knowhow more comprehensively by itself.

Nilgiri

INT'L MOD

- Aug 4, 2015

- 25,762

- 48,113

- Country of Origin

- Country of Residence

IMO...Turkiye is like India's aerospace R&D, but run competently, very competently @Oscar The Turkish 'babus' get sidelined very quickly, and there's a top-to-bottom obsession to developing indigenous solutions to safeguard national interests. In addition, there is also a strong level of synergy between public and private sector actors.

I'll tag you later in thread to continue this in longer chat way for Pakistan and India more specifically.....Pakistan has intense unique version of it compared to India, which is stagnating Pakistan extra severely now.

But it will get off topic for here.

Turkish basic capital + HR per capita intensity is lot higher than subcontinent....for its MIC to leverage off. Less anti-intellectualism, scapegoating and other phenomenon present that Oscar describes too in the "work culture" and larger psyche present.

We won't agree on the other points but which engine is this? XF9?

Please don't count an engine in development that was not put in serial production at least.

Japan has now given up independently developing its own next-gen fighter and the partnership with the UK/Italy will rely on an engine built on core Rolls Royce technology.

Yes the XF9.

Japan did successfully develop it, it just wasn't put into production from the reports we read the Japanese said it hit all benchmarks.

Japan hasn't "given up", they have merged their program with the British to save money, as well as develop an even more advanced Variable cycle engine with the UK. That engine is going to be on par with the same GE XA100 and P&W XA101 engines currently being developed for the NGAD and if the F-35 ever gets reengined in the future. Japan chose to do this rather than put the XF9 into production, as while it would have matched the F119 more or less, it would have been a generation begin the XA100 and XA101 variable cycle engines.

Yes the XF9.

Japan did successfully develop it, it just wasn't put into production from the reports we read the Japanese said it hit all benchmarks.

Japan hasn't "given up", they have merged their program with the British to save money, as well as develop an even more advanced Variable cycle engine with the UK. That engine is going to be on par with the same GE XA100 and P&W XA101 engines currently being developed for the NGAD and if the F-35 ever gets reengined in the future. Japan chose to do this rather than put the XF9 into production, as while it would have matched the F119 more or less, it would have been a generation begin the XA100 and XA101 variable cycle engines.

I think "successfully" develop is not quite accurate as they run a bench test back in 2017 from what I can gather.

P&W run a bench test of the F-22s F-119 back in 1993 but the fighter was not put into service till 2005, although the engine was in serial production a little before then. It took even the US a whole decade till they were confident in the performance and reliability of the F-119 before it went into mass production around 2003-2004.

As for Japanese input into the variable cycle engine, I am afraid the really complex and hi-tech stuff will go to the UK's Rolls Royce who are on a par with P&W and GE. Remember that Roll's Royce even designed and developed 40% of the other engine for the F-35 that was ultimately not selected. Yes Japan will get the 2nd most important engine work but you can be sure that the core and turbine blade tech will all be developed by the UK's Rolls Royce.

Japan would have been able to have a 5th generation engine ready by the 2030s but they are a fair bit ahead of the Turks, since as well as licence production for many decades(IHI) of both civilian and military jet engine parts, they actually successfully developed turbofans for both military trainer aircraft and Patrol aircraft such as Kawasaki-P1. Also remember that since Japan could not reach high enough thrust levels for the F7 turbofans they had to put 4 engines on each patrol aircraft, rather than 2 CFM turbofans on larger ASW aircraft such as the Poseidon P8.

Turkey will have to create a miracle to have a reliable and high-performance 35,000lb class engine for the KAAN in the 2030s. They would need to go down the F110-GE-129/WS-10B 30,000lb class route first before taking around another decade to reach 35000lb class engine.

.

As for Japanese input into the variable cycle engine, I am afraid the really complex and hi-tech stuff will go to the UK's Rolls Royce who are on a par with P&W and GE. Remember that Roll's Royce even designed and developed 40% of the other engine for the F-35 that was ultimately not selected. Yes Japan will get the 2nd most important engine work but you can be sure that the core and turbine blade tech will all be developed by the UK's Rolls Royce.

Japanese fifth generation nickel base single-crystal superalloy is ahead of anything Europeans has fielded so far afaik. and RR didn't developed the turbine section of F136. It was from GE.

I think "successfully" develop is not quite accurate as they run a bench test back in 2017 from what I can gather.

P&W run a bench test of the F-22s F-119 back in 1993 but the fighter was not put into service till 2005, although the engine was in serial production a little before then. It took even the US a whole decade till they were confident in the performance and reliability of the F-119 before it went into mass production around 2003-2004.

As for Japanese input into the variable cycle engine, I am afraid the really complex and hi-tech stuff will go to the UK's Rolls Royce who are on a par with P&W and GE. Remember that Roll's Royce even designed and developed 40% of the other engine for the F-35 that was ultimately not selected. Yes Japan will get the 2nd most important engine work but you can be sure that the core and turbine blade tech will all be developed by the UK's Rolls Royce.

Japan would have been able to have a 5th generation engine ready by the 2030s but they are a fair bit ahead of the Turks, since as well as licence production for many decades(IHI) of both civilian and military jet engine parts, they actually successfully developed turbofans for both military trainer aircraft and Patrol aircraft such as Kawasaki-P1. Also remember that since Japan could not reach high enough thrust levels for the F7 turbofans they had to put 4 engines on each patrol aircraft, rather than 2 CFM turbofans on larger ASW aircraft such as the Poseidon P8.

Turkey will have to create a miracle to have a reliable and high-performance 35,000lb class engine for the KAAN in the 2030s. They would need to go down the F110-GE-129/WS-10B 30,000lb class route first before taking around another decade to reach 35000lb class engine.

The Production engines were ready in 1997 not 2003 or 2005. The F-22 went into Service in 2005 not b/c of the engine getting delayed or b/c of how difficult it was to build or anything like that, if anything P&W's design for the engine was more conventional on purpose to avoid longer dev line and reliability issues, compared to the F120 that GE was building with Variable cycles.

The delay in service came from Budget cuts in the post soviet political space and the lack of urgency for fielding a fighter(China was not a threat at that point, it hadn't even built 4th gen fighter at that point, and Russia was in complete freefall).

And idk where you are getting these timelines at that Japan would not have an engine until the 2030 etc etc. Are you an aerospace engineer or something? whats your source for this timeline? I never heard from a Japanese aerospace engineer at IHI or any Japanese publication saying they would only be able to develop it by the 2030s. You are just making stuff up, and discounting statements actually made by the TEI engineers who are giving a different timeline, now granted their timeline is optimistic, but they did meet their timeline in the delivery of the TS1400 turboshaft and they are on schedule regarding TF6000 so far.. They might miss it by a few years, they aren't going to miss it by a decade in all likelyhood. These people have actual technical indepth knowledge and expertise, they aren't random people giving their opinions. And btw, where is this stuff about the not being able to develop engines until after the 2030s or how Japan can't build one until the 2030s coming from?

Also the Japanese chose the 4 engine configuration not b/c they can't build a 2 engine configuration but b/c of their own requirements and prioritization. 4 engine configurations are not as economical, but they offer their own unique advantages, namely low speed maneuvering and reliability in the event of an engine failure. If you are building something from scratch, in many instances, its better to have 4 engines than 2. For example Boeing Built the C17 with 4 PW2000 engines, not b/c more powerful engines weren't available for example they could have gone with the PW4000, but they chose the configuration they did for its own benefits. You will notice the 2 engine layout of military aircraft is usually more often not a dedicated build but something that was chosen from a civilian build that was then repurposed to save costs rather than build from scratch.

Last edited:

Eşbah

INT'L MOD

- Dec 26, 2023

- 410

- 560

- Country of Origin

- Country of Residence

All in all, Japan is unmatched to this day when it comes to Metallurgy. It doesn't surprise me given the fact that such traditions go back 1500 years.Japanese fifth generation nickel base single-crystal superalloy is ahead of anything Europeans has fielded so far afaik. and RR didn't developed the turbine section of F136. It was from GE.

Early Japanese iron-working techniques - Wikipedia

Here's an article from 8 years back on the Rolls Royce's work on Single-crystal casting.Japanese fifth generation nickel base single-crystal superalloy is ahead of anything Europeans has fielded so far afaik. and RR didn't developed the turbine section of F136. It was from GE.

Zarvan

Elite Member

- Apr 28, 2011

- 55,592

- 65,607

- Country of Origin

- Country of Residence

If KAAN comes with internal weapons bay than it won't be. South Korean KF21 has everything stealth except for internal weapons bay. It would soon come. If KAAN directly comes with internal weapons bay than it would be 5th Generation Jet.Hi,

KAAN aircraft is a level below the 5th gen aircraft category---. You may call it a 4.5 Gen +++ or a 4.75 Gen +++ type of aircraft---.

It is similar to the So Korean aircraft---.

Zarvan

Elite Member

- Apr 28, 2011

- 55,592

- 65,607

- Country of Origin

- Country of Residence

Latest J-20 are coming with WS 15 engine which were meant for a 5th Generation Fighter Jet.All the people saying KAAN isn't 5th Gen b/c of GE F110s, should understand that the F-35 has a lower top speed than the KAAN, as well as a lower Thrust to Weight Ratio if I'm not mistaken. It also doesn't have supercruise like the F-22.

The J-20 also uses WS-10s and AL-31s and is considered a 5th gen fighter. despite the fact that those engines are from the same generation as the F110 engine.

So people need to have a consistent criteria on what elements they are using to define the criterion.

L

LegionnairE

Guest

All in all, Japan is unmatched to this day when it comes to Metallurgy. It doesn't surprise me given the fact that such traditions go back 1500 years.

Early Japanese iron-working techniques - Wikipedia

en.m.wikipedia.org

it's insane how we're still finding ways to make better steel after thousands of years.

Some people think that there wasn't any iron working in the bronze age. There was.

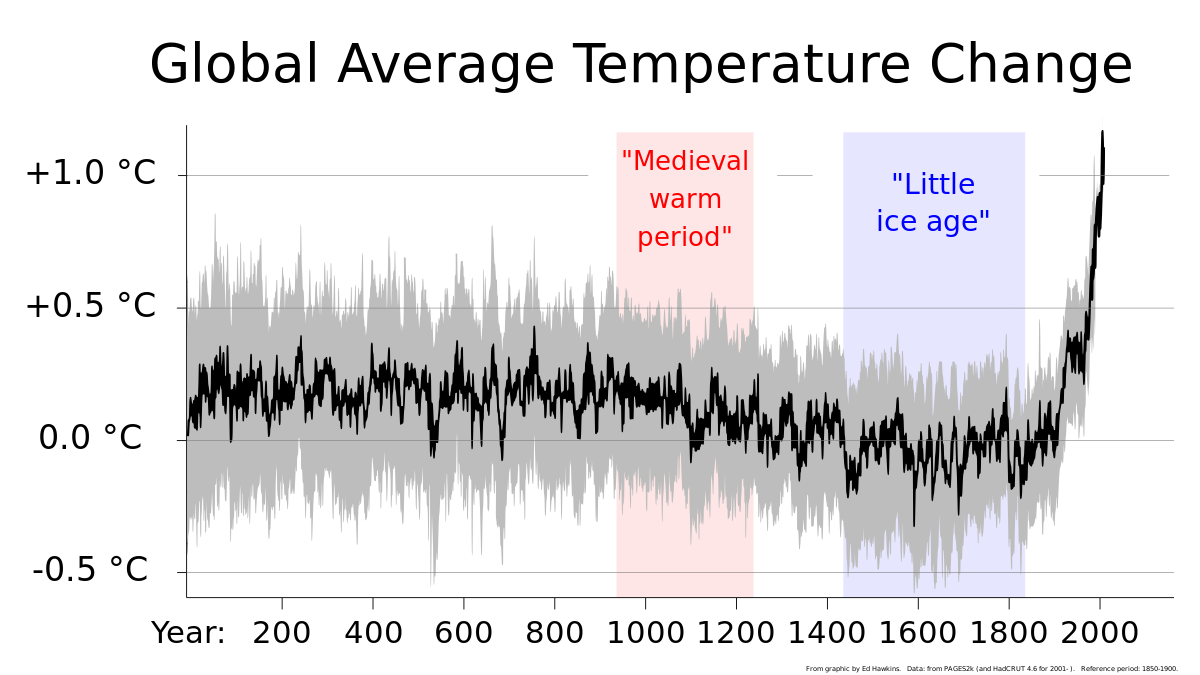

It's an extremely old technology. But it really got going after the little ice age

Little Ice Age - Wikipedia

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)

Pakistan Defence Latest

-

-

-

Indian general praises professionalism of Pakistani peacekeepers in South Sudan (6 Viewers)

- Latest: Cookie Monster

-

-

Country Watch Latest

-

-

Not just engines, Tejas Mk-1A delivery could be hit over key Danish part, now on export blacklist (5 Viewers)

- Latest: Thinking

-

Strategic Defense Options for Small Economies: How Can Bangladesh Effectively Defend Itself? (1 Viewer)

- Latest: Thinking

-

-